-

Điện - Tự Động hóa

Điện - Tự Động hóa

- Chi tiết danh mục

- Đèn Chiếu Sáng Tủ Điện - Máy

- Đầu Cắm Kết Nối Công Nghiệp

- Dây Dẫn Điện

- Xích Đi Dây Điện

- Thiết Bị Bôi Trơn - Bảo Dưỡng

- Xy Lanh Điện - Phụ Kiện

- Động Cơ - Servo

- Motor Bơm Nước - Hóa Chất

- Nguồn Điện

- Cảm Biến - Công Tắc Công Nghiệp

-

Module - Mạch Điện Công Nghiệp

- Thiết Bị Giải Nhiệt - Sấy Tủ

- Bộ Phát Xung Điều Khiển

- Vật Tư Điện Điều Khiển

- Thiết Bị Đóng - Cắt Điện

- Biến Tần - Điều Chỉnh Tốc

- PLC - HMI

-

Cơ Khí - Tự Động Hóa

Cơ Khí - Tự Động Hóa

-

Vật Tư Khí Nén

Vật Tư Khí Nén

-

Vỏ Tủ - Vật Tư Làm Tủ Điện

Vỏ Tủ - Vật Tư Làm Tủ Điện

-

Khung Định Hình - Băng Tải

Khung Định Hình - Băng Tải

- Chi tiết danh mục

-

Khung Định Hình Tròn

-

Khung Định Hình Vuông

-

Khung Nhôm Định Hình

-

Khung Nhôm Mặt Bàn

-

Tán - Nut Nhôm Định Hình

-

Ke Góc Nhôm Định Hình

-

Đế Tấm Nhôm Định Hình

-

Chân Đế - Tăng Chỉnh

-

Bánh Xe Nhôm Định Hình

-

Nắp Che Đầu Nhôm Định Hình

-

Ron Che Rãnh Nhôm Định Hình

-

Băng Tải - Linh Kiện

-

Tay Siết - Núm Vặn

-

Lưới - Hàng Rào Bảo Vệ

-

Linh Kiện Siết - Nối

Linh Kiện Siết - Nối

-

Dao Cụ Cắt Gọt

Dao Cụ Cắt Gọt

-

Dụng Cụ Cầm Tay

Dụng Cụ Cầm Tay

-

Máy Công Cụ

Máy Công Cụ

-

MKZ - Maker Zone | Thiết Bị Học - Training

MKZ - Maker Zone | Thiết Bị Học - Training

- Chi tiết danh mục

- Robotic Frames

- Mạch Lập Trình

-

Module - Mạch Cảm Biến

- Combo Cảm Biến

- Cảm Biến Vân Tay

- Cảm Biến Áp Suất

- Cảm Biến La bàn

- Cảm Biến Gyro - Gia Tốc

- Cảm Biến Độ Ẩm - Nhiệt Độ

- Cảm Biến Nước - Mưa

- Cảm Biến Ánh Sáng

- Cảm Biến Âm Thanh

- Cảm Biến Touch

- Cảm Biến Trọng Lượng

- Cảm Biến Lưu Lượng

- Cảm Biến Từ - Kim Loại

- Cảm Biến Đếm - Encoder

- Cảm Biến Vị Trí - Định Vị

- Cảm Biến Khí - Môi Trường

- Cảm Biến Điện Áp - Dòng Điện

- Cảm Biến Chuyển Động - Rung

- Cảm Biến Khoảng Cách - Vật Cản

-

Module - Mạch Điện Tử

- LCD Màn Hình Hiển Thị

- LED - Matrix Hiển Thị

- Đồng Hồ Đo - Hiển Thị

- Mạch Nguồn - Điều Chỉnh

- Mạch Relay - Đóng Ngắt

- Mạch Điều Khiển Động Cơ

- Mạch Nạp Dữ Liệu Chip

- Mạch Truyền - Nhận Dữ Liệu

- Mạch Chuyển Đổi Dữ Liệu

- Truyền Nhận - Âm Thanh

- Phím Bấm - Keypads

- Van Điện - Công Tắc Điện

- Mạch Đệm - Cách Ly Tín Hiệu

- Mạch Khuếch Đại Tín Hiệu

- Dụng Cụ Hàn Cell - Đóng Pin

- Dụng Cụ - Phụ Kiện DIY

- Thiết Bị STEM

- Thiết Bị - Nội Thất Maker Place

-

Linh Kiện Chuyên Dụng CNC

Linh Kiện Chuyên Dụng CNC

-

Linh Kiện Chuyên Dụng Laser

Linh Kiện Chuyên Dụng Laser

- Chi tiết danh mục

-

Vỏ - Bàn Máy Khắc Laser

-

Nguồn Laser Khắc

-

Thẻ Điều Khiển Laser Khắc

-

Galvo - Scanner Laser Khắc

-

Mở Rộng Và Hội Tụ Tia Laser

-

Ống Kính - Lens Laser Khắc

-

Khung - Bàn Máy Cắt Laser CO2

-

Nguồn Laser Cắt - Khắc CO2

-

Bộ Điều Khiển Máy laser CO2

-

Ống Phóng Laser CO2

-

Gá - Thấu Kính Laser CO2

-

Trục Xoay Khắc Laser

-

Linh Kiện Chuyên Dụng 3D Printer

Linh Kiện Chuyên Dụng 3D Printer

-

Nguyên Liệu - Vật Liệu

Nguyên Liệu - Vật Liệu

-

Thiết Bị Đo - Kiểm Tra

Thiết Bị Đo - Kiểm Tra

- Chi tiết danh mục

-

Dưỡng Kiểm Tra

-

Bàn Map - Bàn Kiểm Tra

- Dụng Cụ Đo - Độ Dày

- Dụng Cụ Đo - Chiều Dài

- Dụng Cụ Đo - Góc Nghiêng

-

Dụng Cụ Đo - Khoảng Cách

-

Dụng Cụ Đo - Điện Áp Dòng Điện

-

Dụng Cụ Đo - Trọng Lượng

-

Dụng Cụ Đo - Lực

-

Dụng Cụ Đo - Cường Độ Sáng

-

Dụng Cụ Đo - Tốc Độ

-

Dụng Cụ Đo - Độ Ẩm Nhiệt Độ

-

Dụng Cụ Đo - Chất Lượng Không Khí

- Dụng Cụ Đo - Bề Mặt Vật Liệu

-

Máy Tính - Viễn Thông

Máy Tính - Viễn Thông

-

Thiết Bị - Vật Tư Nhà Xưởng

Thiết Bị - Vật Tư Nhà Xưởng

-

Hóa Chất Vệ Sinh - Dầu - Mỡ

Hóa Chất Vệ Sinh - Dầu - Mỡ

- Trang chủ /

- Bộ Điều Khiển Tủ Điện CNC /

- CARD ĐIỀU KHIỂN MULTECH

CARD ĐIỀU KHIỂN MULTECH

Thông Tin Sản Phẩm

CARD ĐIỀU KHIỂN MULTECH là board điều khiển máy CNC khắc gỗ, làm quảng cáo..vv, hỗ trợ sử dụng trực tiếp các chương trình như Autocad, corelDraw và các phần mền CAD/CAM khác.

Thông số kỹ thuật CARD ĐIỀU KHIỂN MULTECH

Features:

1, the basic configuration for the three axes of motion (rotation axis can be added, namely 4-axis motion control card),

2, automatic processing. Full support for the ISO standard G commands, HP plotter (HP PLT) format and carved processing (ENG) format.

3, manual function. Both supported by machine input devices, such as handheld devices and other manipulation tools, also supported by the embedded computer input devices such as a keyboard, mouse, complete manual operation.

4, incremental feed function. User to accurately set the feed rate and step size can be flexibly adjusted.

5, the user data input (MDI) function. Online users can enter and execute G command immediately.

6, advanced processing instructions. Simply enter a few parameters, you can complete end milling, Crochet and other functions.

7, single-step mode. Users can set up processing tasks to be performed for the single-step mode, so as to fault diagnosis and recovery provides a good support.

8, breakpoint memory, hops execution advanced automatic functions.

9, save / restore functions workpiece origin.

10, the axis precision mechanical origin return (reference point) function.

11, automatic tool function. These features give the user processing provides great convenience.

12, to adjust the feed rate online. In the process the user can adjust the feed rate. 0 to the minimum, equivalent to suspend processing; up to 120%.

13, high-speed smooth speed connectivity features. In a general numerical control system, the connection speed between two G command is usually a fixed value (such as zero or a certain small value). In the new CNC system, using a unique processing speed adaptive prediction algorithm. The algorithm is based on the size of the connection speed, direction, maximum acceleration, and forward prediction function adaptively determines the current speed of convergence between instruction and the next instruction. Not only greatly improve the processing efficiency (from approximately 30% to 300%), but also improve the processing performance, eliminating the left in the machined surface speed chatter.

14, 3D simulation display function. By a simple operation can be observed from all angles, three-dimensional processing results, which can be more accurate and more intuitive understanding of the machining results.

15, the simulation function. Machining program can quickly simulate machining, can in a very short period of time, while checking for errors and processing procedures, processing the results are satisfactory, and can accurately calculate the time required for the actual processing.

16, a powerful, flexible keyboard support. The new version supports keyboard operations on very strong. Meet user needs during the operation.

17, the log function. The system provides a powerful logging features to help users view detailed processing information and system diagnostics.

18, built-in processing file manager. Users simply save the machining program file to the specified directory, HcaverM? Can manage these files in a built-in manager.

19, built-in file editor. The user can at any time within the processing files transferred editor to edit, modify.

20, Document processing information. Through simulation or actual machining, file machining information can help user statistics window Files Important time, processing range execution.

21, PCI bus motion control card.

Advanced Features

1. The increase in the work function points

Step 2. Add custom mobile

3. The increase comes with an array of processing (a single open-source software G can customize an array of N G codes from the column spacing can be freely set)

4. Increase the software direct reading DXF file without third-party software to convert the two-dimensional

5. The increase of fixed function knife

Kích thước sản phẩm

Từ khóa sản phẩm:

-Mạch điều khiển máy cnc

-MULTECH P1 V2.1.0

Chính sách bảo hành:

Sản Phẩm Liên Quan

Bộ Điều Khiển Máy CNC XCMCU - XC809DF 6 Trục

Car Stuidio V8

Bộ Điều Khiển Máy Cắt CNC PLASMA F2300A

Bộ Điều Khiển USBmach3 DDMACH3 CNC

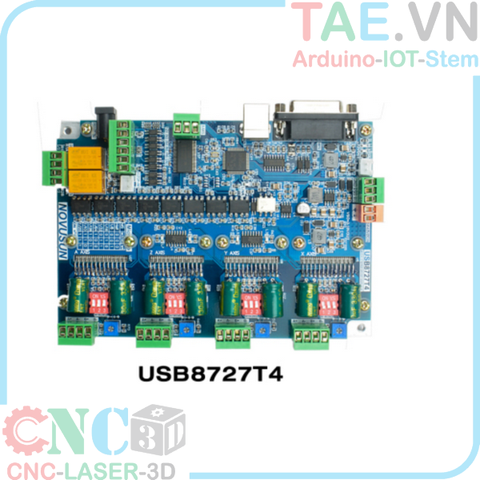

Bộ Điều Khiển USB Mach3 CNC USB8727T4

Bộ Điều Khiển Máy CNC NCH-02

Mạch Điều Khiển CNC USB Mach 3 NC200

Bộ Điều Khiển USB Mach3 UC300

Bộ Điều Khiển Mach 3 Ethernet 6 Trục EC500

Tay Cầm Điều Khiển CNC

Bộ Điều Khiển CNC DDCSV 3.1

Bộ Điều Khiển Máy Tiện CNC XCMCU609T 4 Trục